Join or Sign In

Sign in to customize your TV listings

By joining TV Guide, you agree to our Terms of Use and acknowledge the data practices in our Privacy Policy.

11 TV Shows Like Evil to Watch if You Like Evil

Let them possess you

Have you heard the good news about Evil? It's back on May 23. The bad news is that the upcoming fourth season will be the last for Robert and Michelle King's sublime Paramount+ drama, but it's getting four extra episodes (bringing the season up to 14 episodes total) to bring the story to a close — if closure is even possible on this show.

Evil — which stars Katja Herbers, Mike Colter, and Aasif Mandvi as a trio of investigators looking into claims of demonic activity on behalf of the Catholic Church — is the coolest procedural on TV. While you wait for its return, you could always rewatch the whole show (and tell your friends), but if you've already done all that, it couldn't hurt to find a similar show to enjoy. TV Guide has rounded up a list of shows that scratch the same kind of itch, whether you're on the hunt for more exorcisms, horror homages, skeptic-and-believer partnerships, or just really weird crimes.

More recommendations:

Mrs. Davis

Betty Gilpin, Mrs. Davis

Tina Thorpe/PeacockHave more fun with Catholic imagery with Mrs. Davis. A bonkers, intoxicating joyride through tech and religion starring the great Betty Gilpin as a nun fighting an AI algorithm, Mrs. Davis marries the comic and dramatic sensibilities of its creators, Tara Hernandez (The Big Bang Theory) and Damon Lindelof (The Leftovers), into an audaciously weird package. There's a confident playfulness to Mrs. Davis that makes it feel a lot like Evil, and not just because Katja Herbers shows up to deliver a deliciously go-for-broke performance. Both shows also dig into spirituality in similar ways, exploring their characters' beliefs with both winking blasphemy and piercing sincerity. This show is an experience too surprising to spoil, except to say it's got everything from a quest for the Holy Grail to mid-tier Reno magicians, and it builds to a gag so brilliant it could make a believer out of anyone. -Kelly Connolly

Fringe

Fringe

FOX Image Collection via Getty ImagesTrade the supernatural for science fiction with Fringe, a thrilling deep dive into the evils — and the wonders — made possible by science. Anna Torv plays Olivia Dunham, an agent with the FBI's Fringe Division, who enlists scientist Walter Bishop (John Noble) and his son, Peter (Joshua Jackson), to consult on strange cases. The series started as mostly a case-of-the-week procedural, but, like Evil, it was too ambitious to be contained by standalone stories alone. As it embraced its destiny as a twisty serialized epic about parallel universes, Fringe grew into one of the best and most underappreciated dramas of its era. Like Evil, it revels in getting weird. Plus, since the drama on Fringe is rooted in the catastrophic consequences of one man's attempt to save his child, it should appeal to fans of Kristen Bouchard (Herbers) and her deadly protectiveness of her four daughters. -Kelly Connolly

Midnight Mass

Hamish Linklater, Midnight Mass

NetflixIf you want another show that deals explicitly with the intricacies of Catholicism, Midnight Mass is a good bet. Mike Flanagan's limited horror series is set on a remote fishing island in New England that is shaken up by the arrival of a priest (Hamish Linklater), who quickly gains hordes of devoted followers in the community as he seemingly begins to perform miracles. But nothing is ever what it seems on a Flanagan show, and it quickly becomes clear that there's a sinister threat looming over the island, each episode unfolding with a certain amount of gripping eeriness. Midnight Mass is less interested in jump scares than it is in examining religion and faith. It's all very Stephen King, despite King not being involved in any way. -Allison Picurro

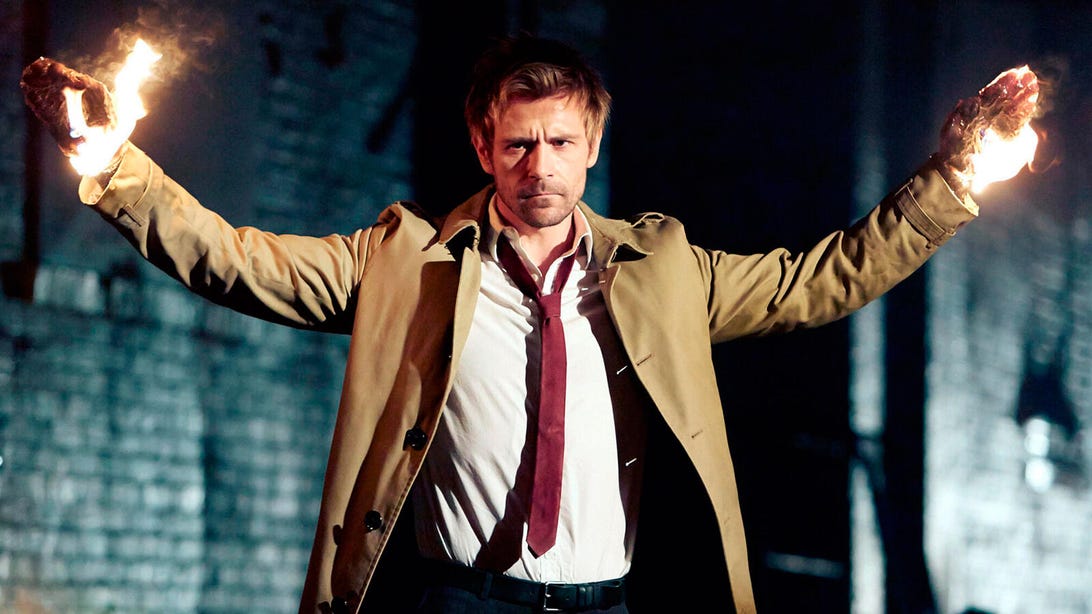

Constantine

Matt Ryan, Constantine

Quantrell Colbert/NBCLooking for another irreverent thriller about demonic activity? The short-lived NBC drama Constantine stars Matt Ryan as occult detective John Constantine, who travels the country battling supernatural threats in the hopes of saving his own soul. Ryan was such a hit in the role that after this show's cancellation, he eventually resurrected the character on DC's Legends of Tomorrow, becoming a series regular. But Constantine is all Constantine all the time, and it's packed with action, Biblical lore, atmospheric scares, and, yes, exorcisms. It's a little uneven, but Ryan's performance anchors it. -Kelly Connolly

The Good Wife and The Good Fight

Christine Baranski, Andrea Navedo, The Good Fight

CBS/Paramount+If you're ready to go deeper into the minds of Evil creators Robert and Michelle King, start with The Good Wife and The Good Fight, a pair of legal dramas that share Evil's winking sense of humor. The Good Wife follows Julianna Margulies' Alicia Florrick as she returns to her law career after her husband is involved in a political scandal; its spin-off, The Good Fight, switches focus to Christine Baranski's Diane Lockhart as she takes a job with a Black-owned law firm in the age of Trump. In addition to featuring plenty of actors who also pop up on Evil (including Mike Colter), the two shows engage with the hypocrisies and absurdities of the world in a way that should make Evil fans feel right at home. If you love Evil, you should see what it takes to be Good. -Kelly Connolly

Outcast

Patrick Fugit, Outcast

CinemaxDuring the resurgence of horror TV series (and TV in general) in the mid-2010s, Cinemax got into the act with Outcast, a project from The Walking Dead creator Robert Kirkman that was based on his comics of the same name. Like Evil, it's mostly about demonic possession, and like Evil, it's deliciously F'd up. Patrick Fugit stars as Kyle Barnes, a man whose life has been plagued with unwanted spiritual invaders possessing his family and his hometown of Rome, West Virginia. It's darker than Evil, but still probes questions of the inherent nature of evil and the secrets we keep rather than pinning it all on a singular baddie. It only lasted two seasons, but it's a solid religious-based look at demonic possession. -Tim Surette

The Exorcist

Alan Ruck and Geena Davis, The Exorcist

Chuck Hodes/FOXYou've seen the movie, but have you seen the TV show? Fox's two-season follow-up to the 1973 horror classic flew under the radar when it aired in 2016 and 2017, but it's worth a watch: a spooky, well-acted tale of crises of faith and haunted families. Geena Davis plays the matriarch of a family with something dark going on beneath the surface, so she recruits a pair of priests — played by Ben Daniels and Alfonso Herrera — to rid her home of demons. The first season twists that premise in surprising directions, especially for fans of the film. But The Exorcist only gets stronger when it leaves that storyline behind in Season 2 and leans into Daniels and Herrera's rapport. -Kelly Connolly

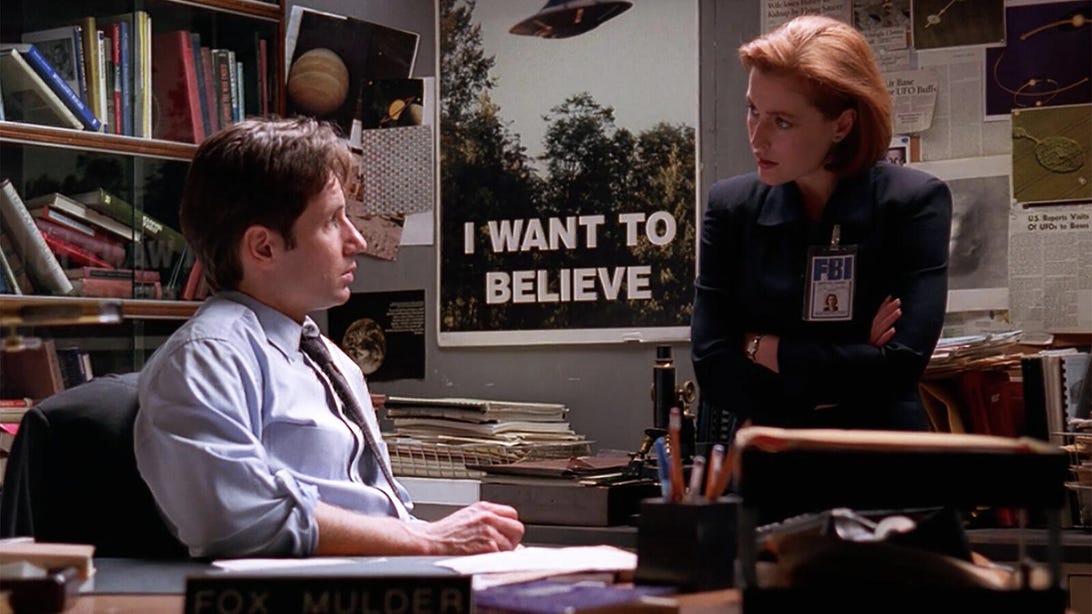

The X-Files

David Duchovny and Gillian Anderson, The X-Files

FoxYou had to know this list would get here eventually. The X-Files' Mulder (David Duchovny) and Scully (Gillian Anderson) are TV's definitive believer and skeptic, paired up to investigate paranormal phenomena for the FBI. On the surface, Evil is basically a riff on The X-Files with exorcisms instead of alien abductions. It's not just the spooky cases; both shows share a deep-down fear that something is wrong with the world, and that people in authority are lying about it for their own benefit. Decades after its premiere, The X-Files' moody blend of monsters and government paranoia is as relevant as ever. And while Evil is more playful, The X-Files isn't above poking fun at itself, either — especially in the episodes written by Darin Morgan, whose absurd sense of humor is right in line with Robert and Michelle King's. Evil fans looking for a taste of The X-Files might want to start with one or two of Morgan's episodes; we recommend the Season 3 Emmy winner "Clyde Bruckman's Final Repose." -Kelly Connolly

Hannibal

Mads Mikkelsen and Hugh Dancy, Hannibal

Brooke Palmer/NBCU Photo Bank/NBCUniversal via Getty ImagesBefore Season 1 of Evil, which aired on CBS, pushed the limits of what a network procedural could be, Hannibal did the same on NBC. Bryan Fuller's lavish drama, where the dead bodies are as elegantly composed as the food, built up a cult following for its tangled, transgressive exploration of romance and violence. The series focuses on the complicated love between Hannibal Lecter (Mads Mikkelsen) and the FBI profiler hunting him, Will Graham (Hugh Dancy), a relationship that increasingly brings out their most self-destructive instincts. The horror here is gorier than on Evil, but the shows are united by their ability to spin a scary story into something more provocative and weird. Though fans have been clamoring for more Hannibal since its cancellation, the Season 3 finale is, to my taste, the perfect ending. -Kelly Connolly

Buffy the Vampire Slayer

Nicholas Brendon, Anthony Head, Sarah Michelle Gellar, Charisma Carpenter and Alyson Hannigan, Buffy the Vampire Slayer

Fotos International/Courtesy of Getty ImagesIf you love Evil's knack for turning ghost stories into metaphors for modern anxieties, watch Buffy, where the ghost stories are metaphors for growing up. The classic coming-of-age drama follows Buffy Summers (Sarah Michelle Gellar), who fights the vamps and demons in her town — which happens to be situated over a Hellmouth — as part of her calling as the Slayer, all while navigating homework and prom and really bad breakups. Like Evil, Buffy loves horror, and it uses the conventions of the genre to explore how scary real life can be. It's also daring, funny, and unafraid to take its characters to unexpectedly dark places. Evil isn't the kind of procedural that needs everything to be OK at the end of the hour. Neither is Buffy. -Kelly Connolly